- PRODUCT CENTER

- Stone crushing machine

- Sand making machine

- Powder making machine

- Ore dressing machine

- Cement Production Line

- Tel: 0086-371-67833171

- E-mail: machine@hxjq.com

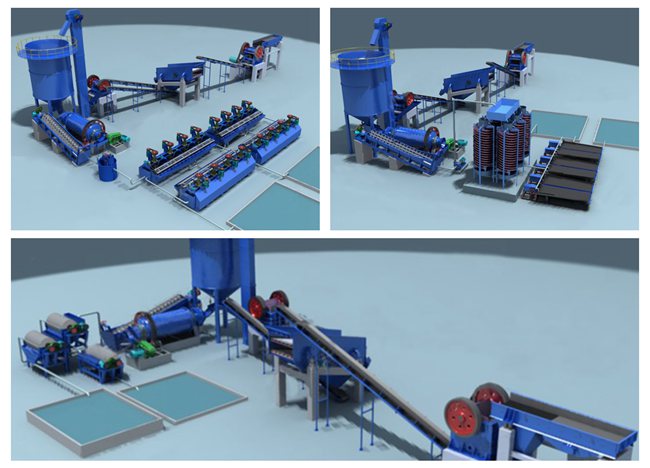

Ore Beneficiation

Ore processing plant is necessary in the mineral beneficiation or ore beneficiation. Hongxing ore beneficiation plant includes magnetic separators and gravity separators. The magnetic separator includes magnetic ore separator and common magnetic separator and gravity separator includes shaking table and jigger machine.

- Features

Collections Of Ore Processing Plant

Ore processing plant is necessary in the mineral beneficiation or ore beneficiation. Hongxing ore beneficiation plant includes magnetic separators and gravity separators. Hongxing Machinery also has other mineral beneficiation plants like stone crusher, grinding mill, vibrating screen and sand washing machine.

Iron Ore Beneficiation Technology

Almost all of the iron ores are used in steelmaking. Iron ore is mined in about 50 countries. Australia and Brazil together dominate the world's largest iron ore exports, each having about one-third of the total exports. The banded iron formations are found throughout the world and are the most important iron ore in the world today. Mining and processing involves coarse crushing and screening. Magnetite is beneficiated by crushing and then separating the magnetite from the gangue minerals with a magnet. This is so efficient that lower grade ore can be treated when it is magnetite rather than a comparable grade of hematite ore, especially when the magnetite is quite coarse.

Steps Of Ore Separating Line

Digging ore from the earth is only half the battle. The processing of the ore is often just as challenging and expensive, which takes place in refineries, smelters and mills. Ore processing consists of the following stages:

1. Crushing and grinding of the ore;

2. Addition of process water (generally decanted from the tailings pond) to form a slurry;

3. Addition of lime to the ore, and cyanide solution to the slurry, to leach the gold and silver into solution;

4. Addition of carbon to adsorb dissolved metals;

5. Stripping the metals from the carbon by acid washing and circulation of a caustic cyanide solution;

6. Precipitation of the gold and silver by electro-winning;

7. Smelting of metal products into bars;

8. Pumping of the barren slurry (tailings) to the tailings storage facility.

- Leave A Message